Casting Innovation, Shaping the Future.

Cold Chamber Die Casting Machine

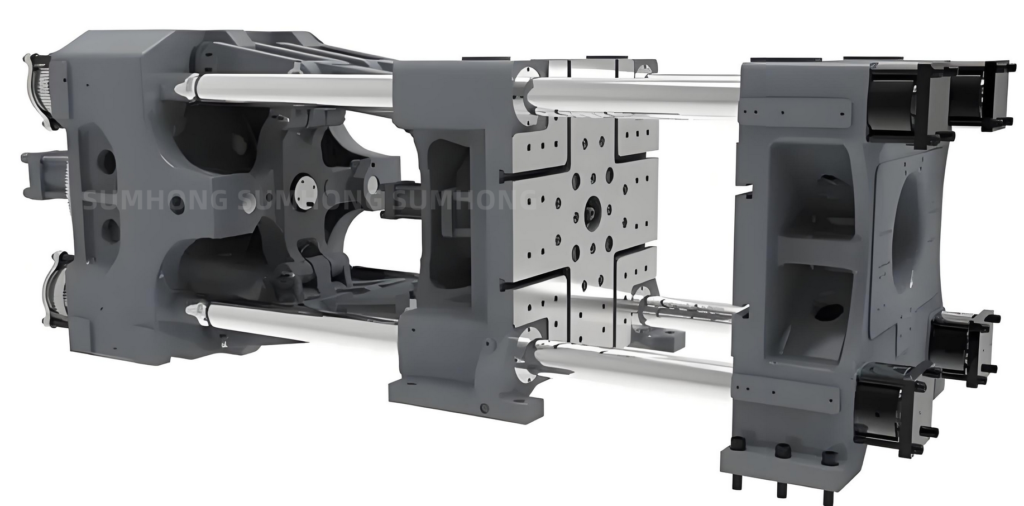

SH-Series High Performance

Cold Chamber Die Casting Machine

User-Friendly

Easy-to-use interactive system

High-Performance

Up to 40% with innovative hydraulic.

Advanced Technology

Intelligent real-time control system

Durable & Reliable

Long-lasting Operational Lifespan

Cold Chamber Die Casting Machine Main Features

- Modular Structure Design: Customizable configurations to meet specific product requirements.

- High Injection Speed: Maximum injection speed of ≥8m/s; Boost pressure build time: ≤20ms (large machines), ≤15ms (small machines).

- Enhanced Injection System: Faster and more stable with multi-point settings and multi-stage controls, providing a wide adjustment range and strong adaptability.

- Independent Injection and Boost Circuits: Minimized interference for improved injection stability.

- Highly Integrated Hydraulic System: Efficient, energy-saving design that simplifies maintenance and servicing.

- Upgraded Dual-Elbow Clamping Mechanism: Smooth, fast, and powerful mold movements.

- Reinforced Durable Design: Enhanced template and elbow systems for increased durability.

- Fast Clamping Technology: Shortened production cycles and improved efficiency.

- Waterproof and Dustproof Guide Column Automatic Ejection Device: Standard on large machines, optional on small machines, suitable for large molds.

- Dual Hydraulic Cylinder Ejection System: Provides even ejection force.

- Optional Automatic Clamping Force Adjustment: Efficient and responsive mold adjustments.

- Standard Interfaces for Peripheral Equipment: Comprehensive die-casting unit solutions available.

- Standard 15L Large Lubrication Oil Tank: Ensures reliable and efficient operation.

Top-Quality Hydraulic Components

Our die-casting machines use world-leading hydraulic components from brands such as Rexroth, Tokyo Keiki, and Yuken. Equipped with high-performance, low-noise pumps, these components ensure stable pressure and flow, enhancing the overall reliability of the machine.

Precision Non-Contact Displacement Sensors

Our machines feature non-contact displacement sensors that provide highly accurate and repeatable measurements. This advanced technology ensures precise speed and displacement conversions, optimizing the performance of the die-casting process.

Large Capacity Energy Storage System

The die-casting machines are equipped with a large-capacity energy storage system that delivers rapid pressure build-up and high speed with minimal pressure drop. This ensures a stable and efficient pressure and speed throughout the casting process.

High-Precision Proportional Valves

Fast injection and pressure boosting are controlled by high-precision electronic proportional valves. These valves offer easy screen-based settings and adjustments, ensuring high stability and ease of use. (Standard on large machines, optional on smaller machines).

Innovative Box-Type Template Design

The machine features an innovative box-type template design with added thickness for enhanced rigidity, strength, and stability. This robust construction extends the machine’s lifespan and performance.

Reinforced Hinge Design

Our die-casting machines include reinforced hinges and template ears, which distribute stress more evenly and reduce deformation. This design improvement increases the machine’s impact resistance and durability.

Increased Mold Space

With a larger mold cavity design, our machines accommodate a wider range of molds and reduce the chances of material splashing. This feature enhances the versatility and efficiency of the casting process.

Patented High-Tensile Alloy Steel Guide Columns

Our machines utilize specially designed high-tensile alloy steel guide columns, This innovation extends the lifespan of the columns and improves the overall durability of the machine.

Advanced Control System

Equipped with top-tier electrical control components from Siemens and Omron, our machines offer rapid response times, high control precision, and strong interference resistance. The control system is designed to operate reliably in harsh environments with minimal maintenance and low failure rates.

Parameter List

SUMHONG Integrated Die Casting System